CFD analysis to support the bike designer

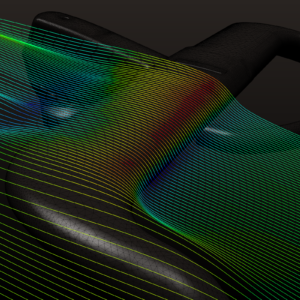

Computational fluid dynamics analysis (CFD) is a simulation technique applied also in the sporting goods industry. Roughly summarized, CFD consists in discretizing a volume of fluid in many cells (in the order of millions for a bicycle) and solving for each cell a series of equations until the convergence of the calculation. Skeptics will say that in most cases for the bike industry it’s just Colorful Fluid Dynamics for mere marketing purposes, but one should not confuse what is shown on “the surface” with what is actually studied and kept confidential in order not to give precious informations to the competitors.

The growing availability of computational power at low cost and the maturity reached nowadays by simulation softwares allows for a depth of analysis that professional bike designers and product development teams cannot ignore. Especially in a highly competitive market where marginal gain is increasingly determining the difference between a success (sporting and/or commercial) and a mediocre result or, worse, a debacle.

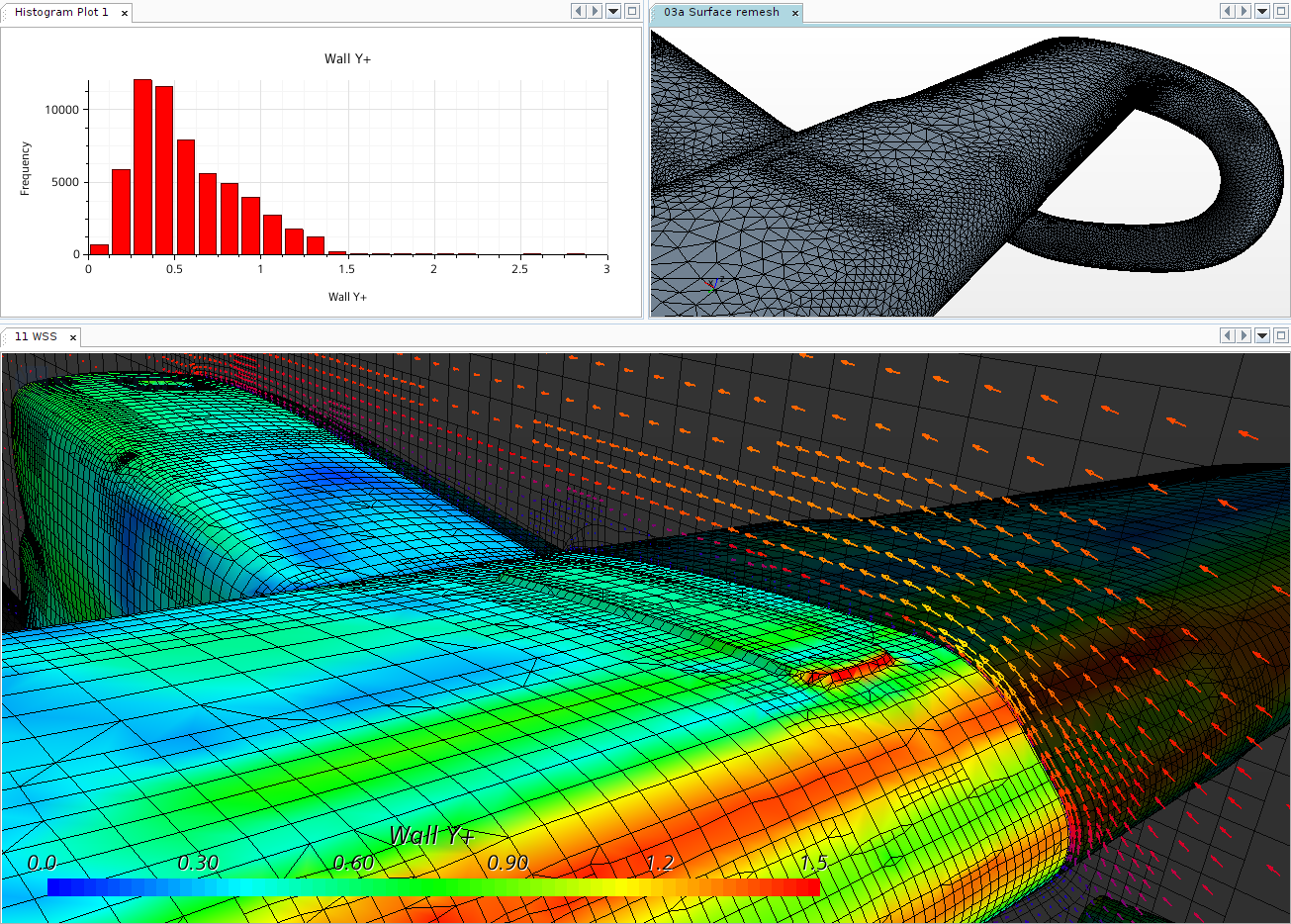

Before CFD became an accessible tool, the traditional approach to evaluate the aerodynamics of a bicycle involved the use of the wind tunnel. This had a strong impact on costs and few possibilities to proceed with a wide comparative development. Unless you have an unlimited budget, the use of the wind tunnel alone places severe limitations on the possible design variants to be compared. However, the tunnel remains a fundamental reference for providing the experimental feedback necessary for the so-called “calibration” of numerical models. Given the variety of possible modeling approaches and parameters (type of mesh, type of analysis, turbulence and transition models for the boundary layer, etc.) it would be naive to blindly trust a numerical result without any experimental validation. Or, more frequently, without an experimental reference that allows to tune such parameters so that the model becomes reliable.

So where is the usefulness of CFD if it still requires experimental feedback?

Here’s the good news: given a fluid dynamics problem (i.e. a bicycle at a certain range of speed and wind angles), after tuning a model over a reference experimental setup, it is not that modifying the frame or a component will radically alter the physics of the problem itself. Especially if the changes are within UCI rules. Once the model parameters have been correctly tuned and the underlying physics has been properly chosen, the model is sufficiently robust and reliable even for subsequent design changes. In addition, modern CFD analysis softwares have now evolved in the direction of providing an integrated platform for optimization: this allows to explore a large design space in a time frame that was unthinkable even just 10 years ago.

Gregario offers B2B consultancy activities to the cycling industry including his knowledge and experience in fluid dynamics analysis. Working with Siemens StarCCM+ for CFD, Gregario is able to support the entire product design cycle with detailed analysis and accurate reporting of the aerodynamics development of frames and components. All with traditional 100% armored confidentiality that distinguishes a faithful Gregario.